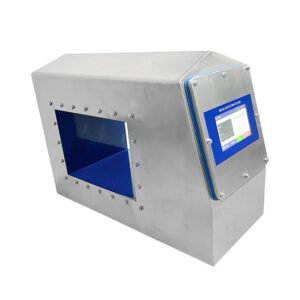

Industry Metal Separator Machine (RT-1213)

Gravity Fall Metal Detector

Device Description

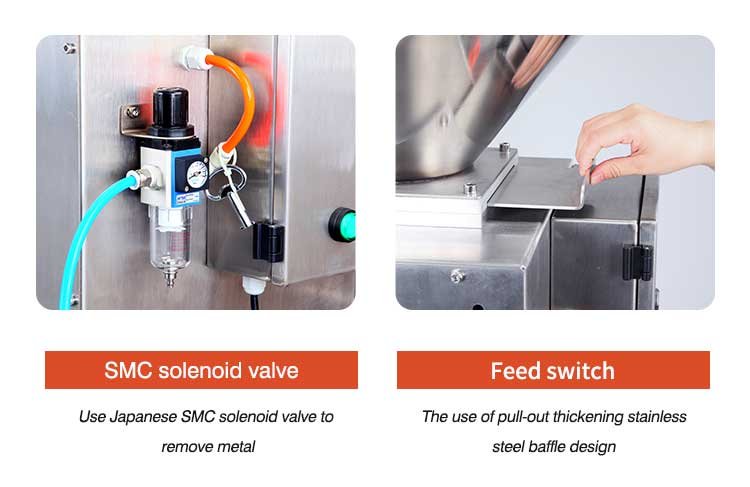

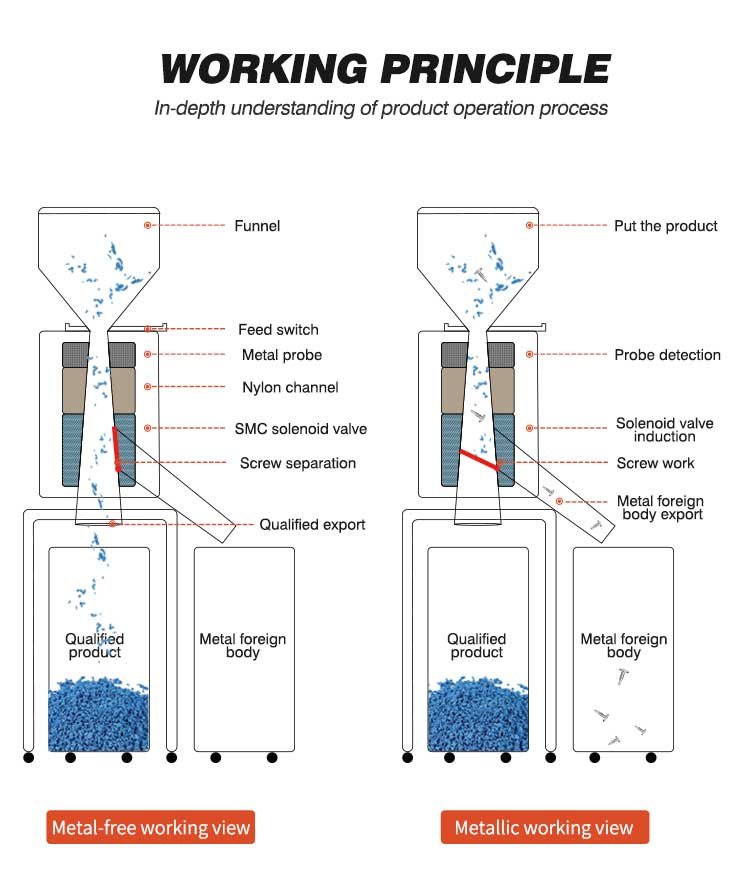

The metal separation system removes magnetic and non-magnetic metal impurities (steel, stainless steel, aluminum, etc.) from the free-falling bulk material through a turret funnel without any interference with product handling. This has proven to be a particularly effective method of removing impurities from grain, light, fragile and wet bulk materials.

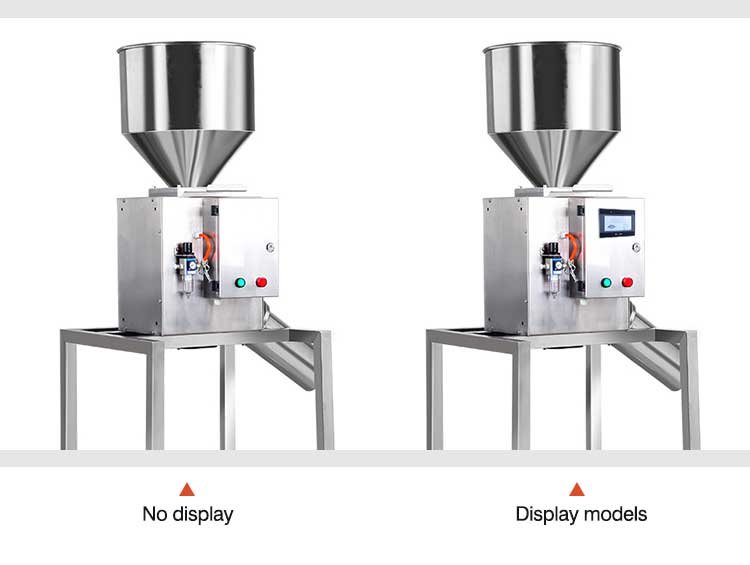

Product Details:

RT-1213 Professional Granular Material Metal Separator

This machine is used in food, chemical, and other industries to test raw plastic materials, especially fine-grained powders. It can remove metal contamination from products such as popcorn, nachos, potato chips, nuts, whole grains, fruits, and pasta soups. It can separate various metals, including iron, copper, stainless steel, and aluminum, with a minimum detectable metal size of 0.3mm. The machine’s sensitivity can be adjusted to meet specific production needs, offering fast response speed and high precision. Additionally, it is small, easy to install, and can be directly mounted on equipment.

Product Parameters:

Sensitivity And Production Capacity

|

Feed Opening

|

Production capacity

|

Detect Sensitivity (Iron :Fe Cooper:Cu Stainless Steel:SUS)

|

|

35mm

|

300kg/hr

|

Fe:0.3mm Cu0.3mm SUS:0.8mm

|

|

50mm

|

800kg/hr

|

Fe:0.5mm Cu0.5mm SUS:1.0mm

|

|

70mm

|

1800kg/hr

|

Fe:0.8mm Cu0.8mm SUS:1.5mm

|

|

100mm

|

2500kg/hr

|

Fe:1.2mm Cu1.2mm SUS:2.0mm

|

|

150mm

|

5000kg/hr

|

Fe:1.8mm Cu1.8mm SUS:3.5mm

|

Machine Parameters

Gas consumption: 0.4 liters per separation action

Protection level: IP54

Separation time: 0.2-2.5 seconds, 0-10 stepless adjustable detection accuracy

Controller Parameter

RT-1213 Industrial Plastic Powder Particle Metal Separator Advantages

- Products containing long fibers do not block the discharge equipment.

- Avoid disorder and product agglomeration (light and thin products)

- Hygienic design, venting device rustproof and waterproof

- Avoid prolonged product accumulation and moldy mold

- Quick and easy cleaning by cleaning the sheets

Start earning substantial profits in your country today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

Related products

-

Walk Through Metal Detector (RT-1220 )

-

Toe Metal Detector The Smallest Shoe Nail Detector Machine (RT-1207 )

-

Safeline Pipeline Metal Detector With Rejector (RT-1213C)

-

Food X-ray Metal Detector (RT-1211B)

-

Aluminum Foil Packaging Metal Detecting Machine (RT-1212)

-

Automatic Online Checkweigher (RT-1215)

-

Button Type Food Metal Detector Head (RT-1209C)

-

Touch Screen Food Metal Detector Head (RT-1209B)

Product Categories

- 1000 X 1000mm Tunnel X-ray Screening Machine (1)

- 1000 X 800mm Tunnel X-ray Screening Machine (1)

- 500 X 300mm Tunnel X-ray Screening Machine (1)

- 650 X 500mm Tunnel X-ray Screening Machine (1)

- 800 X 650mm Tunnel X-ray Screening Machine (1)

- Check Weigher (3)

- Food Metal Detector (6)

- Food X Ray Scanner (1)

- Metal Separator (2)

- Needle Detector (7)

- Walk Through Metal Detector (1)