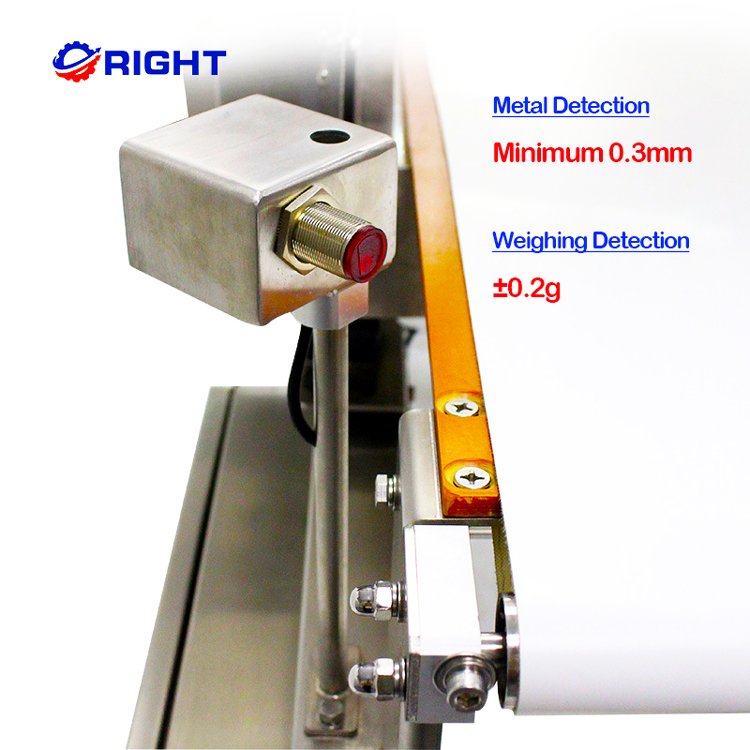

Combined Metal Detector And Checkweigher (RT-1215G)

Additional information

| Model | RT-1215G |

|---|---|

| Transfer Method | Conveyor Belt |

| Language | Chinese/English/Korean/Spanish etc. |

| Customized Cupport | OEM, ODM, OBM |

| Brand Name | DGRIGHT |

The main functions of the combined metal detector and checkweigher machine.

1. Detect the metal impurities (such as iron, non-iron, copper and aluminum, stainless steel, etc.) mixed into the product.

2. Automatically detect the abnormal net weight of products.

3. Automatically detect product overloading/underloading abnormality.

4. Automatically detect the missing parts of the accessory parts of the product, and miss the quality of the abnormalities of loading.

Product Details:

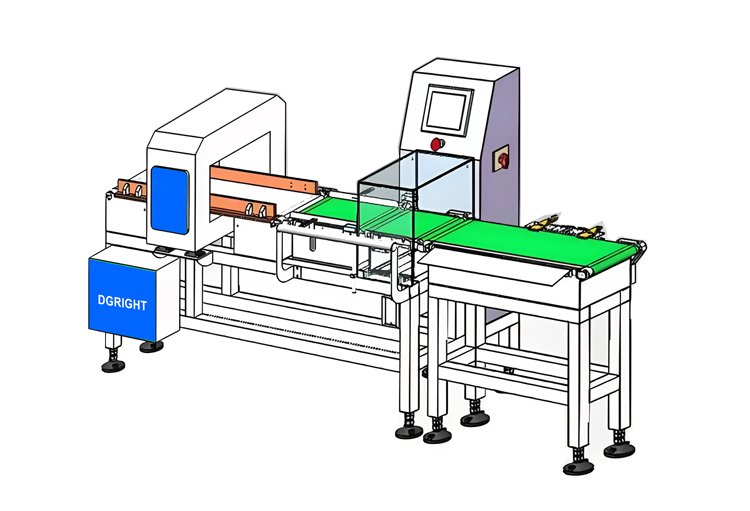

Metal Detector Checkweigher Combo System

Product Introduction:

RT-1205G Metal Detector And Checkweigher Machine is mainly used to check the weight of packaged products and all-metal foreign objects in them. It is a high-sensitivity detection equipment that can simultaneously detect the weight of packaged products and all-metal foreign objects, including ferrous metals (such as iron) and non-ferrous metals (such as copper, aluminum, and stainless steel). In addition, it can also detect metal film packaging such as aluminum foil to ensure product quality and safety.

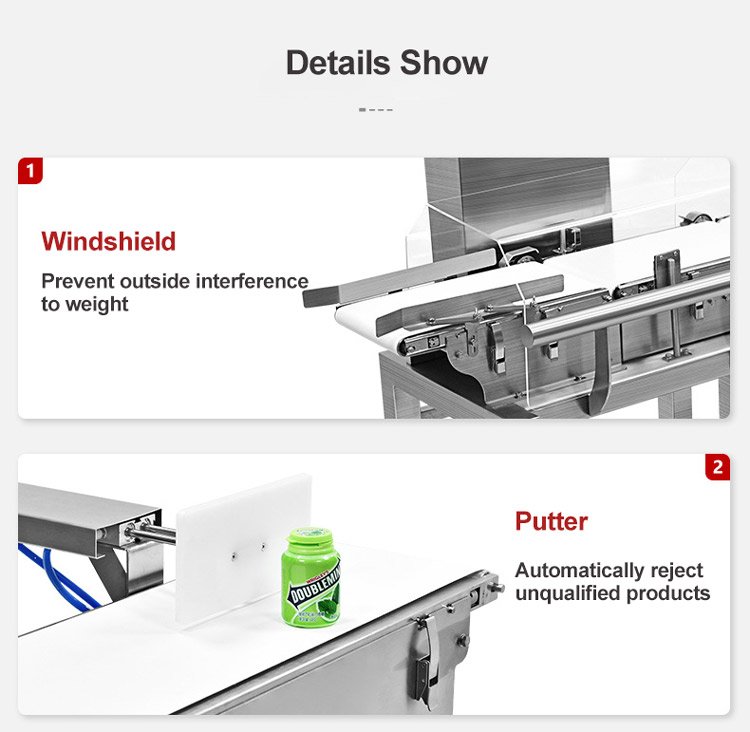

The RT-1215G check weigher and metal detector combination has a stable and highly sensitive detection function, as well as a self-learning function and user-friendly operation interface, enabling it to play an important role in industrial production lines. The screen directly displays weight and metal detection results, and it can store 2000 sets of product data, as well as perform weight classification and statistics. The dust-proof display and stainless steel body of this device make it easy to use and maintain, and it is suitable for a wide range of production environments.

Why We Are The Best Automatic Check Weigher And Metal Detector Machine?

- Strong universality: the standardized structure of the whole machine and standardized man-machine interface can complete the weighing of various materials;

- Simple operation: using the Weilun color human-machine interface, fully intelligent and humanized design; the conveyor belt is easy to disassemble, convenient to install and maintain, and easy to clean

- Adjustable speed: the frequency conversion control motor is used, and the speed can be adjusted as required;

- High-speed and high-precision: using high-precision digital sensors, fast sampling speed and high accuracy;

- Zero tracking: Manual or automatic zero reset and dynamic zero tracking;

- Report function: built-in report statistics, the report can generate EXCEL format, can automatically generate a variety of real-time data reports,

- U disk can store statistical data for more than one year, support production status at any time, provide factory parameter setting recovery function, and can

- Store multiple formulas, easy to change product specifications;

- Interface function: Standard interfaces are reserved for easy data management.

- Can communicate with PC and other intelligent devices;

- Self-learning: There is no need to set parameters after creating new product recipe information. Use the self-learning function to automatically set the device’s suitable parameters, and store it for easy recall next time you switch products. (2000 parameter storage entries can be added).

- Operation mode: three operation modes

a. Dynamic mode: normal pipeline mode;

b. Static mode: After the material enters the weighing platform, the weighing platform stops running, and weighing is performed to improve the accuracy, which is suitable for products with less than 20 times per minute;

c. Energy-saving mode: The energy-saving mode can be opened on the basis of modes a and b. Set the time when no material passes the shutdown. When the equipment is idling, it will automatically stop after this time. It will automatically start when the material passes. - Self-detection of failures: self-detection: whether the motor, inverter, AD, sensor and photoelectric are normal and the cause of the failure, and the guide detection of the cylinder, solid state relay, and solenoid valve Convenient for non-professional inspection and maintenance.

- Peripheral equipment communication: Standard RS-485 and RS-232 dual

- Communication port outputs.

1) The RS-485 interface is MODBUS, RTU standard protocol, but the write address (57600bps, 8, N, 1, slave number is 3) can not be modified.

2)The RS-232 interface is a user-defined protocol, and you can set the content of sending instructions by yourself. (57600bps, 8, N, 1) can be modified. - Communication equipment such as an external printer or inkjet printer can also be connected to the front-end and back-end packaging machines and production equipment to feedback the weighing results so that it can automatically modify the formula parameters.

RT-1215G Online Conveyor Metal Detection Weighing Machine

Product Parameters:

| model | RT-1215G |

| power | power:single phase AC200V~240V(110V/380Vcan be customized) |

| rated power | 0.15KW |

| Single weighing range | ≤1500g |

| Highest sorting accuracy | ±0.2g±0.5g |

| Minimum scale | 0.1g |

| Metal Detecting | Fe Ø 0.6mm |

| Non-ferrous Ø 0.8mm | |

| Stainless steels Ø 1.5mm | |

| transfer speed | 30~100m/min |

| Maximum speed | 160 pcs/min |

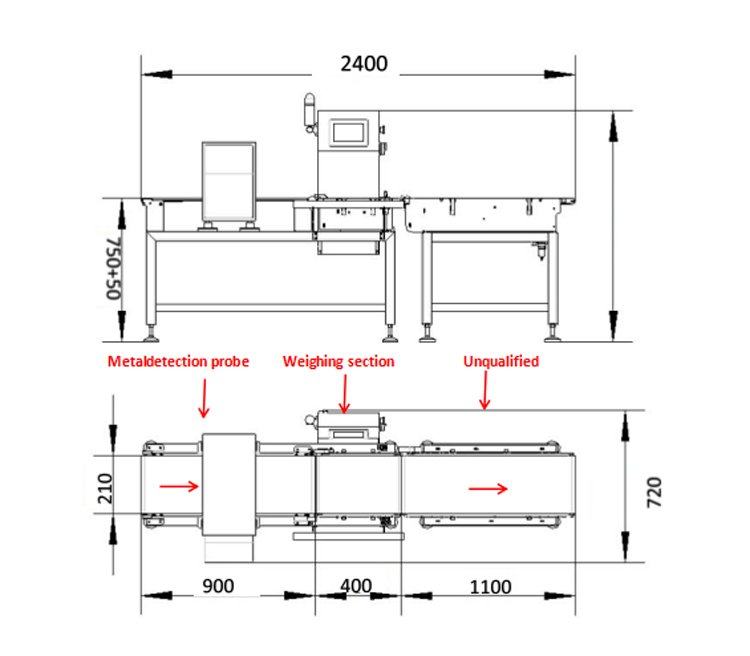

| Metal detection machine channel size | 210mm(W)*120mm(H) |

| Weighing conveyor belt size | 400mm(L)*210mm(W) |

| Machine length | 2400mm(L)*720mm(W)*1222mm(H) |

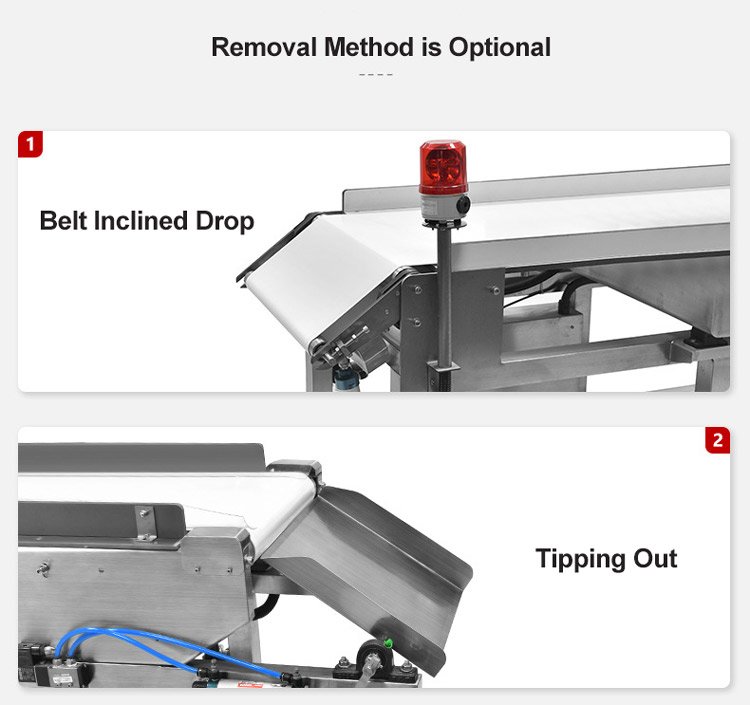

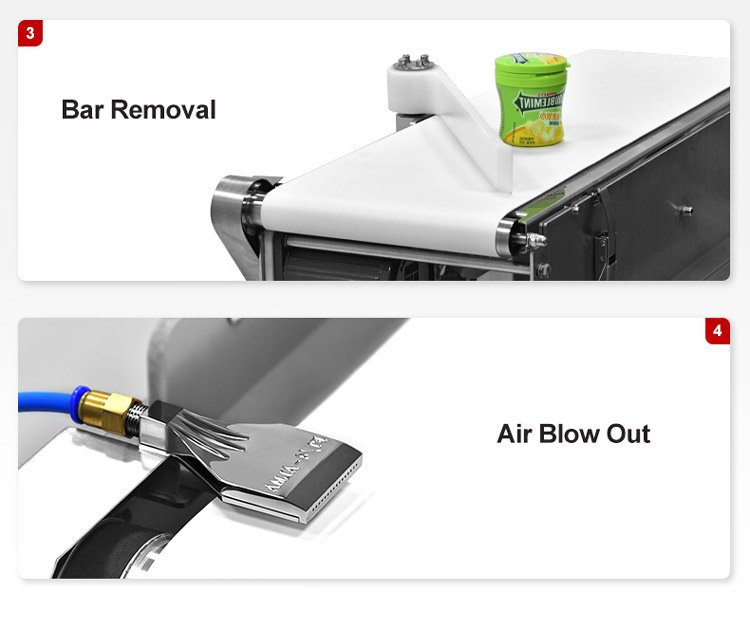

| Elimination method | Putter, swing arm, air blow, split (optional) |

| Control System | High-speed A/D sampling controller |

| Preset product number | 2000pceis |

| Conveying direction | Facing the machine, left to right |

| External air supply | 0.6-1Mpa |

| Pneumatic interface | Φ8mm |

| working environment | temperature: 0℃~40℃,humidity:30%~95% |

| machine material | Stainless steel 304 polishing |

| Operation screen display | Chinese, English, Turkish, Spanish, etc. can be customized |

| Other standard equipment | Windshield (colorless and transparent), calibration weight |

| Belt height from the ground | 750mm~800mm(custom) |

| Protection level | Protection level meets IP-65 international standards |

| Remarks | The accuracy of the detection speed meter is slightly different depending on the size of the product being tested and the working environment in which the equipment is operated |

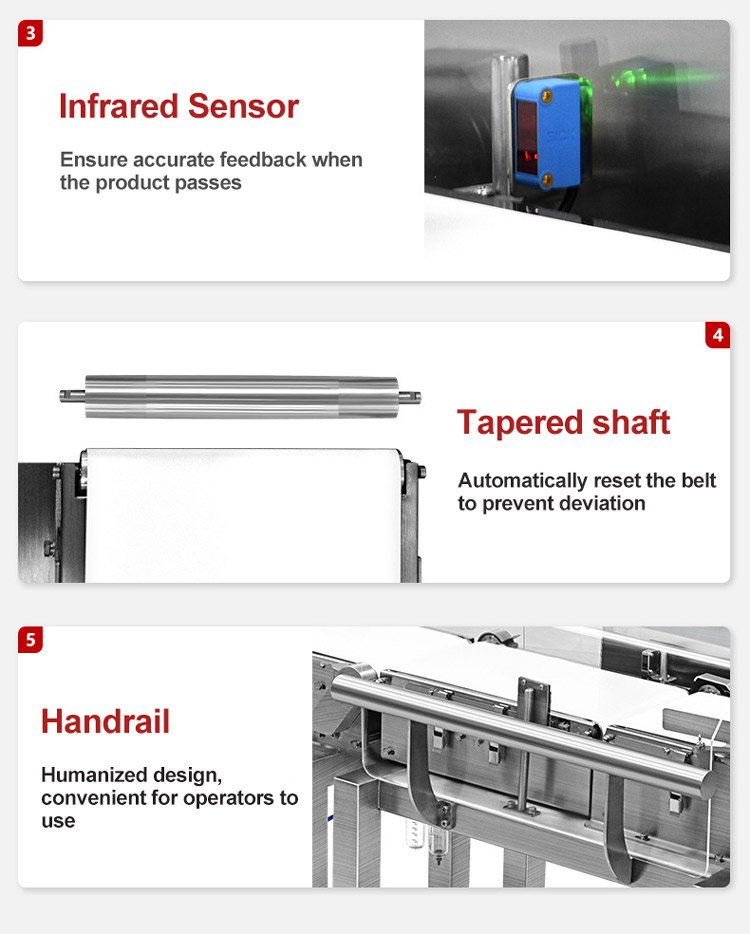

Details Images:

Precise Rejection:

Case Customized For Metal Detection In The Food Industry

Start earning substantial profits in your country today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

Related products

-

Touch Screen Convoyor Belt Mini Checkweigher 0.1g (RT-1215H)

-

Portable Hand Held Needle Detector (RT-1205 )

-

Desktop Needle Detector (RT-1206 )

-

Toe Metal Detector The Smallest Shoe Nail Detector Machine (RT-1207 )

-

Safeline Pipeline Metal Detector With Rejector (RT-1213C)

-

Food X-ray Metal Detector (RT-1211B)

-

Aluminum Foil Packaging Metal Detecting Machine (RT-1212)

-

Touch Screen Food Metal Detector Machine (RT-1209A)

Product Categories

- 1000 X 1000mm Tunnel X-ray Screening Machine (1)

- 1000 X 800mm Tunnel X-ray Screening Machine (1)

- 500 X 300mm Tunnel X-ray Screening Machine (1)

- 650 X 500mm Tunnel X-ray Screening Machine (1)

- 800 X 650mm Tunnel X-ray Screening Machine (1)

- Check Weigher (3)

- Food Metal Detector (6)

- Food X Ray Scanner (1)

- Metal Separator (2)

- Needle Detector (7)

- Walk Through Metal Detector (1)